-

Products

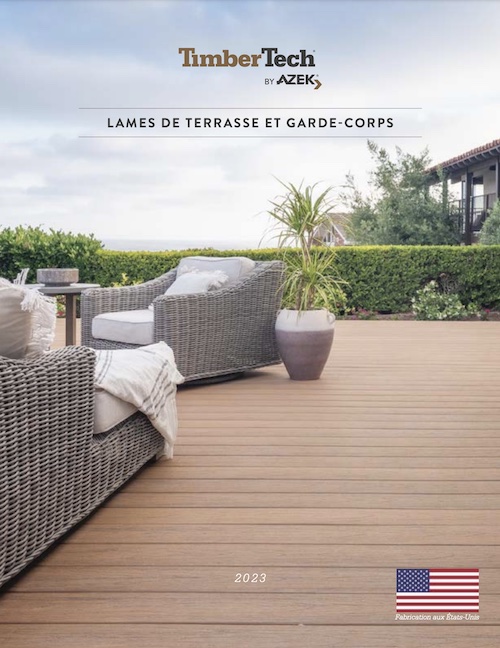

Decking

TimberTech AZEK

TimberTech PRO

TimberTech EDGE

railing

Porch

Lighting

Fastening

Accessories

Free catalog

Request a catalog

Request a catalog

- Inspiration Browse By Colour

-

Resources

Helpful Resources

Register Your Product

Get Started

Care & Cleaning

Get Started

Care & Cleaning

Care and cleaning

Care and cleaning

-

Advantages

Advantages

Our Story

50 years of Coverage

Our Warranty